Revolutionizing Rice Processing: The Rise of the Automatic Rice Mill

In the ever-evolving world of agriculture and food processing, innovation is the driving force behind efficiency and productivity. One such innovation that has transformed the rice processing industry is the Automatic Rice Mill. These advanced machines have not only redefined the rice milling process but have also significantly improved the quality and quantity of output.

India, being one of the largest producers and consumers of rice, has witnessed tremendous growth in rice milling technologies. At the forefront of this revolution is Ricetec Machinery Pvt. Ltd., a trusted name in manufacturing state-of-the-art rice milling equipment. This article delves deep into what an automatic rice mill is, its benefits, components, and why it’s becoming an essential investment for rice millers across the globe.

What is an Automatic Rice Mill?

An Automatic Rice Mill is a modern rice processing system that performs all essential milling operations with minimal human intervention. Unlike traditional rice mills that require manual input for husking, polishing, grading, and sorting, automatic rice mills execute these processes in a streamlined and fully automated manner.

The integration of advanced machinery and digital controls ensures high precision, reduced wastage, and improved efficiency, making it an ideal choice for medium to large-scale rice processing businesses.

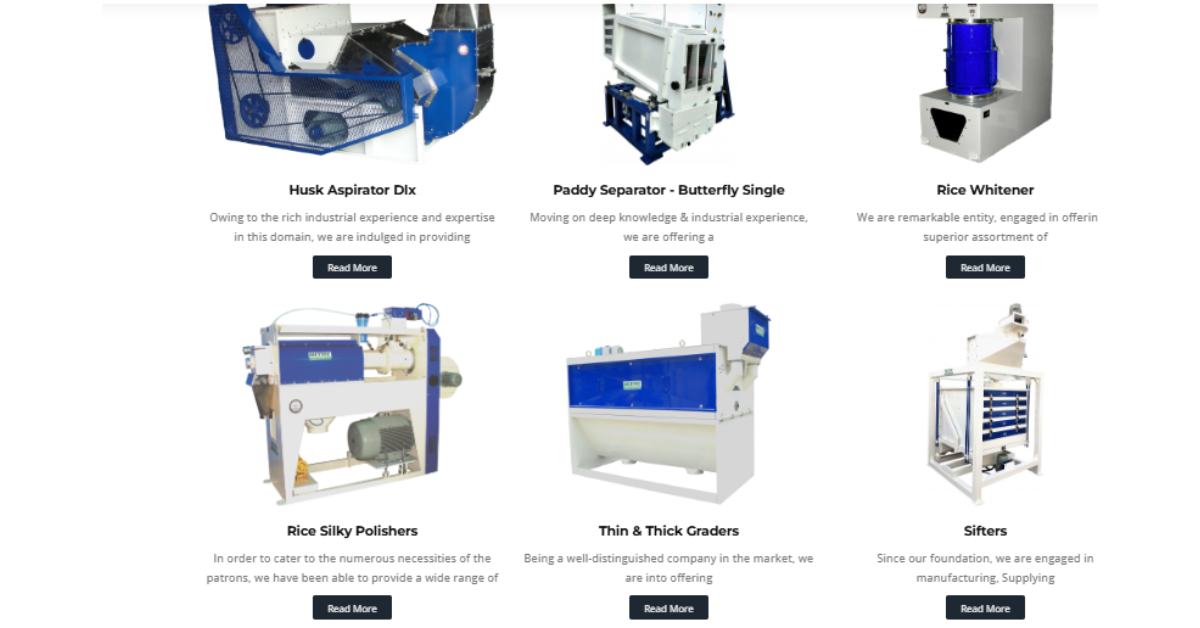

Key Components of an Automatic Rice Mill

Understanding the components of an automatic rice mill is crucial to appreciate how it simplifies the milling process. Here are the primary units typically included in a complete rice mill setup:

1. Pre-Cleaner

Removes impurities such as straw, dust, stones, and foreign materials from paddy before the milling process begins.

2. De-Husker

Separates the husk from the paddy grain. This step is crucial to ensure smooth downstream processing.

3. Paddy Separator

Differentiates between the de-husked brown rice and the paddy, allowing for reprocessing of any remaining paddy.

4. Whitener or Polisher

Removes the bran layers from the brown rice to produce polished white rice. Advanced machines can control the degree of whiteness based on requirements.

5. Grader

Separates rice based on length and quality. Broken rice is separated from full-length grains.

6. Color Sorter

Detects and removes discolored, spotted, or defective rice grains using optical sensors and air jets.

7. Packaging Unit

Automates the packing of finished rice into bags or containers, ensuring hygiene and consistent packaging quality.

Advantages of an Automatic Rice Mill

Switching from a conventional rice mill to an automatic one offers numerous benefits, especially in today’s competitive market. Here are some of the top advantages:

1. Enhanced Efficiency

Automatic rice mills can operate continuously with minimal supervision, increasing throughput and reducing downtime.

2. Consistent Quality

Automated processes ensure uniform milling, grading, and polishing, resulting in consistently high-quality rice output.

3. Lower Labor Costs

With most operations being automated, there’s a significant reduction in manpower requirements, lowering labor costs in the long term.

4. Waste Reduction

Precision machines minimize the breakage of rice and help recover more head rice, reducing overall waste.

5. Energy Efficient

Modern automatic rice mills are designed to consume less power, making them eco-friendly and cost-effective.

6. Customization and Scalability

Ricetec Machinery offers tailor-made solutions to fit varying capacities and operational needs, allowing rice mills to scale efficiently.

Why Choose Ricetec Machinery for Automatic Rice Mills?

Ricetec Machinery Pvt. Ltd. has established itself as a leading manufacturer of rice milling equipment in India and abroad. With a focus on innovation, customer satisfaction, and quality, Ricetec offers a complete range of automatic rice mills suitable for various production scales.

1. End-to-End Solutions

From pre-cleaning to packaging, Ricetec provides a complete range of equipment and services required for a fully functional rice mill.

2. Customization Options

Ricetec understands that each rice miller has unique needs. The company offers customized mill setups based on production capacity, available space, and budget.

3. Advanced Technology

Incorporating the latest technology in automation and digital controls, Ricetec machines ensure high precision, low maintenance, and optimal performance.

4. Technical Support and Training

The company offers comprehensive after-sales service, including installation, training, and regular maintenance to ensure smooth operations.

Applications of Automatic Rice Mills

Automatic rice mills find applications in a wide range of sectors:

-

Commercial Rice Milling Units

-

Government Procurement Centers

-

Export-Oriented Rice Processing Units

-

Modern Retail Supply Chains

-

Agro-Processing Cooperatives

These mills are especially beneficial in regions with high rice production, where processing speed and output quality are crucial.

Future of Rice Milling: Automation and AI Integration

The future of rice milling lies in intelligent automation. The integration of Artificial Intelligence (AI), Internet of Things (IoT), and data analytics is transforming how mills operate. Features such as real-time performance monitoring, predictive maintenance, and remote diagnostics are becoming common in top-tier automatic rice mills.

Ricetec Machinery is investing in R&D to bring smarter, more sustainable rice milling solutions that meet the challenges of tomorrow’s food industry.

Maintenance Tips for Automatic Rice Mills

To ensure optimal performance and longevity, here are some essential maintenance practices:

-

Routine Cleaning: Keep all machinery parts clean and free from dust and debris.

-

Lubrication: Regularly lubricate moving parts to reduce wear and tear.

-

Inspection: Conduct periodic inspections to identify signs of damage or wear.

-

Software Updates: Ensure software and control systems are up to date.

-

Trained Operators: Employ trained personnel to handle operations and troubleshooting.

FAQ: Automatic Rice Mill

Q1. What is the difference between a traditional and an automatic rice mill?

Answer: Traditional rice mills involve manual processing steps, leading to inconsistent quality and higher labor costs. Automatic rice mills use machinery to perform cleaning, de-husking, polishing, grading, and packaging, all in a streamlined, efficient manner.

Q2. Is it expensive to install an automatic rice mill?

Answer: The initial investment may be higher than a traditional mill, but the long-term savings in labor, improved output, and reduced waste make it cost-effective. Ricetec offers various models to fit different budgets and production capacities.

Q3. How much space is required for an automatic rice mill?

Answer: The space requirement depends on the production capacity and machinery layout. Ricetec provides customized layouts and planning to optimize available space.

Q4. Can Ricetec Machinery help with installation and training?

Answer: Yes, Ricetec offers complete support, including installation, operator training, and after-sales maintenance.

Q5. Are Ricetec machines energy efficient?

Answer: Absolutely. Ricetec’s automatic rice mills are designed for low energy consumption without compromising performance, contributing to both cost savings and environmental sustainability.

Conclusion

The automatic rice mill is not just a technological upgrade—it’s a necessity for modern rice processing businesses looking to compete in a dynamic and quality-driven market. By investing in an automatic rice mill from a reputable manufacturer like Ricetec Machinery, millers can unlock new levels of efficiency, product quality, and profitability.

With years of experience, cutting-edge technology, and a customer-first approach, Ricetec stands out as the ideal partner for all your rice milling needs. Whether you’re setting up a new mill or upgrading an existing one, the future of rice processing begins with automation—and Ricetec is leading the way.